Bio Familia – Inline inspection of müesli packaging

Who Is Bio Familia?

bio-familia AG, the traditional Swiss Müesli manufacturer founded in 1954 and based in Sachseln in the heart of Switzerland, developed the first organic Birchermüesli in 1959 and successfully introduced it to the global market. As a pioneer in the Müesli industry, the company is known for its innovative spirit, Swiss craftsmanship, and commitment to natural, sustainable production. With around 200 employees, bio-familia produces approximately 13,000 tonnes of Müesli each year, which are exported to over 40 countries worldwide. Their Müesli creations, made with a love for nature and attention to quality, are tailored to individual tastes and designed for the whole family to enjoy. To ensure consistently high product quality, bio-familia relies on cutting-edge technology. In collaboration with QualiVision AG, an advanced optical inspection system was integrated into the production line to precisely check every Müesli package—quickly, reliably, and with full documentation.

Premium Quality Meets High-Tech: Vision System Ensures Perfect Müesli Cups

As a traditional Swiss Müesli producer with a strong commitment to quality, bio-familia embraces cutting-edge technology to ensure product safety and consistency. In collaboration with QualiVision AG, an advanced vision inspection system has been seamlessly integrated into the production line. This system inspects every Müesli pack with speed, precision, and full traceability.

Thanks to the new vision inspection system, bio-familia benefits from:

Stronger brand trust through consistently flawless packaging

Reduced risk of complaints by catching errors before products leave the line

Lower operational costs and increased efficiency through real-time error detection and less waste

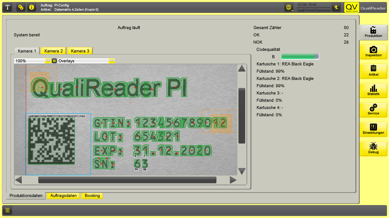

Our vision system offers fully automated, high-precision inspection tailored to the needs of the food industry. It checks the sealing film for correct placement and integrity, verifies printed data such as best-before dates and batch codes, and ensures that all additional labels are present and properly positioned.

Designed to handle natural product variations, the system delivers consistent and robust results without interrupting production. It can be easily integrated into existing lines with minimal disruption. A user-friendly interface and clear production documentation make operation simple and efficient for your team.

Want to see it in action?

More details and real production examples are shown in the video below.